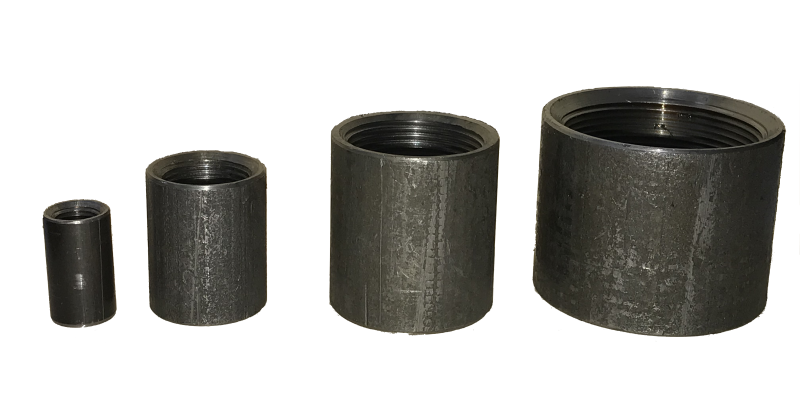

Plumbing systems use a variety of fittings and materials for pipe and tubing. Black iron is perfect for applications that transport gas or water. Professionals will choose black iron over other popular materials like copper, PVC, and aluminum. Here are some good reasons why black iron fittings are important for demanding applications.

This material is coated in black iron oxide, giving it a black appearance. The coating is made through a chemical reaction between iron atoms and oxidizing salts, this creates a coat of magnetite on the surface.

The coat protects the pipe from corrosion and wear, and its corrosion resistance is better than regular cast iron. Black iron pipe is extremely durable. In the right conditions, it can last between 50 and 100 years. Furthermore, it can withstand higher pressures and only starts to melt at 1000 degrees Fahrenheit!

Known for their exceptional strength, durability, and resistance to corrosion, these fittings can handle up to 150 PSI of pressure. This is the same pressure you would feel from a strong water jet used by a fire truck. Since the amount of pressure black iron fittings can handle goes above household plumbing pressure, black iron is used for more demanding applications.

These demanding applications can be:

Black Iron is cost-effective, making it a great choice for piping and fittings used in industrial projects. In addition, the iron is malleable, allowing for installation in tight spaces. The fitting and pipes can easily be put together because they are sealed with a compound instead of welding.

If you are a contractor looking for black iron fittings or pipe, Detroit Nipple Works, keeps large quantities in stock. Please check out our piping chart and request a quote or contact us for more information today!