Do you know what electric-resistant welded tubing is? Detroit Nipple Works does plenty of work in different tubing processes such as drawn-over mandrel and seamless mechanical. However, we also work with electric-resistant welded (ERW) steel and processing. ERW steel goes through a very different process than other tubes, leading it have a distinct difference between stainless steel tubing and other products. So, what is ERW tubing and what is the application of this type of product?

Electric-Resistant Welded steel is a manufacturing process that involves the welding of steel plates together. These plates are welded longitudinally by creating heat through current passing through the contact area. After heating the edges, it welds the two pieces together to form a bond. Pressure is then added to seal the tube properly. You can make ERW tubing out of stainless steel, carbon steel, and other material. There are many advantages to using this type of tubing. These advantages include:

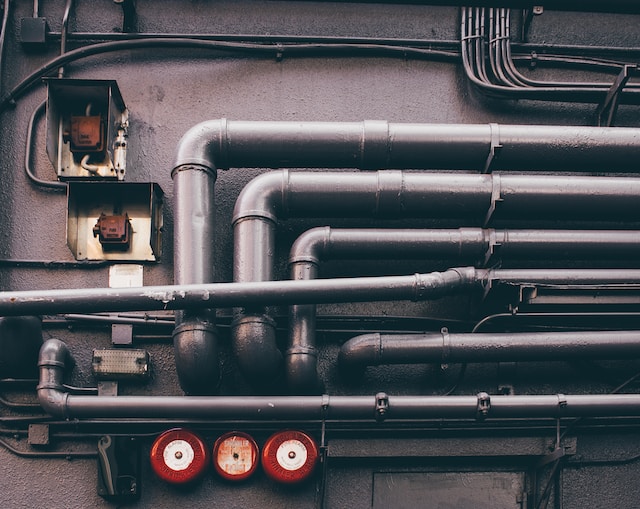

Due to the advantages of manufacturing electric-resistant welded tubing, it can be found in different industries. ERW tubing is an especially popular choice for transporting liquid-gas materials such as oil. The high efficiency makes it capable of handling low and high pressures, making it suitable for transportation pipes. Advancements in this tubing process, ERW has been integrated into pipelines for oil and gas fields. Furthermore, tubing has found a place in the automotive industry as well. ERW tubing is used in constructing automobiles from the steering shaft to the axle.

If you are looking for high-quality ERW tubing for your current project, then you have come to the right place! Since 1934, Detroit Nipple Works has been producing and carrying an extensive inventory of pipes, valves, tubing, and other products. We sell ERW pipe and ship nationwide to our clients. Contact us today to see what we can do for you!

Posted In: Steel Tubing, Welding

Tags: electric resistant tubing, ERW tubing