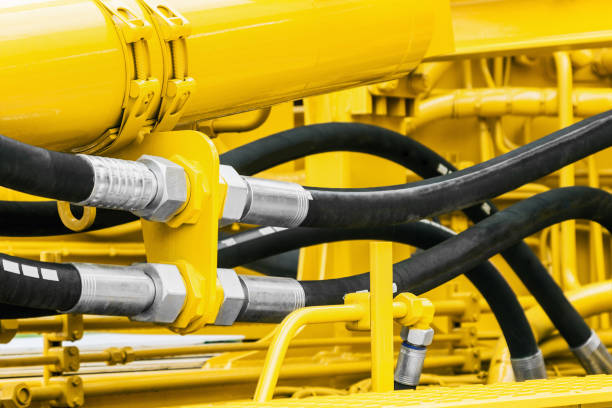

Hydraulic pipe provides transportation for fluid from one component to another. The three main liquids that will pass through a hydraulic pipe include petroleum oil, synthetic oil, and liquid with a high water content. Also, it is a very important part of the hydraulic system. The hose has to be able to tightly bend around all corners. Hose pipe flexibility enables components to be positioned inside the most efficient places, including tight places and across long distances.

Hydraulic pipe provides transportation for fluid from one component to another. The three main liquids that will pass through a hydraulic pipe include petroleum oil, synthetic oil, and liquid with a high water content. Also, it is a very important part of the hydraulic system. The hose has to be able to tightly bend around all corners. Hose pipe flexibility enables components to be positioned inside the most efficient places, including tight places and across long distances.

Hydraulic piping has many uses, the most general being to transfer liquids. In addition, the pipes can be used to transfer energy-generating liquid to different systems to function as a full hydraulic system. For these instances, the pipes and tubes have to be rigid and immobile so the system can be easily controlled. Also, in contrast, construction machinery usually has flexible and open hydraulic tubing so as to allow flexibility and free range of motion.

The type of hydraulic tube depends on its use and the pressures or chemicals it may be subjected to.

Knowing the correct threading of the hydraulic hose is important for repair. Selecting the wrong part can result in damage to the thread during installation. In addition, this negatively affects the pressure holding capacity and seal reliability of the hydraulic fitting. Also, there are six types of threads commonly used on hydraulic tube fittings:

Finally, for more information on hydraulic pipes and threading, contact Detroit Nipple Works today for a free quote!